All You Need to Know About 4 Ply Conveyor Belts

Conveyor belts are the backbone of any industrial procedure, just like the Kilomega's product called Heat Resistant Conveyor Belt. These are useful to move bulk material grain and also products complete a factory or manufacturing plant. Conveyor belts appear in several types and probably one of the most popular is the 4 ply conveyor belt. This short article shall explore the advantages of 4 ply conveyor belts, how it innovates the conveyor belt industry, how to use and maintain it properly, it is applications and quality service.

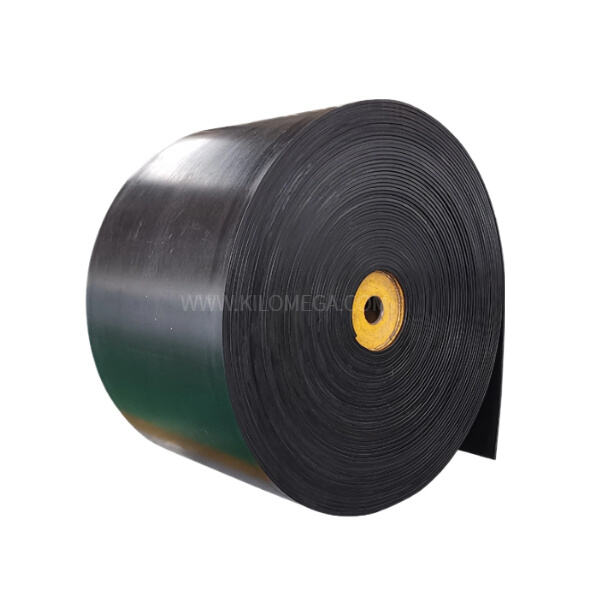

The 4 ply conveyor belt is composed of four quantities of rubber-polyester fabric, similar to the cleated conveyor belt built by Kilomega. Every layer is durable and strong, that will help it be perfect for companies which transportation hefty materials, high volumes of goods. The advantages of the 4 ply conveyor belt include their sturdiness, abrasion opposition and close flexibility. They have been produced by these advantages suited to the mining, cement and steel companies.

Recently, there has been an innovation in the 4 ply conveyor belt production process, that involves the use of high rate technology which guarantees persistence to the quality of this belt, just like the Kilomega's product called idler roller. There is additionally a use regarding the multi-stage procedure that reinforce effectiveness of every layer of this belt, that makes it stronger and more durable. This innovation renders 4 ply conveyor belt more dependable, stable and able to carry weightier lots.

To make sure the safe operation of 4 ply conveyor belt, it is important to follow producer's directions carefully, along with the jaw plate crusher built by Kilomega. First, a few that the belt is installed, maintained and operated correctly. Secondly, safety treatments needs to be put up, such as putting on gloves and sufficient attention to end injuries, although handling the belt and it is add-ons. Lastly, regular maintenance is completed to cease use and tear, which could cause safety dangers.

For optimal efficiency, 4 ply conveyor belts need to feel applied to suitable conveyors and in surroundings which may be not harsh, also the Kilomega's product such as Raw Edge V Belt. The belts should feel stored inside to stop damage and exposure to sunshine and more elements which may degrade the belt. During use, it is important to monitor the belt for damages for instance rips, cuts and punctures; these nagging problems need to become addressed immediately. Regular upkeep includes washing the belt and their add-ons, replacing damaged components and checking for stress and alignment.

can provide a variety of custom-designed products meet 4ply conveyor beltsituations of use. are able to provide expert solutions extensive industry knowledge to help solve challenges of our customers ensure that their production lines operate smoothly.

Ningbo Kilomega 4ply conveyor beltTrade Co.,Ltd has specialization in export Mining, Crusher Plants, and rental production lines rental contracts. We export a full range mine crusher machines spare components, including crushers, belt conveyors, gear boxes, electronic motors, screen mesh conveyor belts, as well as accessories.

company has passed ISO9001, CE, SGS many other certifications. Additionally, company has professional 4ply conveyor beltlines, modern equipment, a skilled group of engineers. also offer 100% factory inspection and the best testing equipment.

Based our 4ply conveyor beltof the whole industry allows us to better assist customers in locating appropriate product (Selected product). Technical support from an excellent technical staff will guarantee that the selected products are in line with requirements of our customers and they satisfied with them in many different circumstances. selection of products is specifically designed to ensure the highest value and quality for your quarry, decrease downtime, extend the life of components and increase productivity.