Conveyor Rollers: Then and Now Conveyor system’s purpose is to carry product, and they do so with unbelievable efficiency. Your rollers will differ depending on what needs to be achieved. Selecting the proper conveyor rollers for your conveyor There is a large selection of rollers on the market and you need to ensure that you select the correct type for your conveyor system. In this article, we’ll delve into the world of conveyor rollers, detailing their functioning and highlighting how to choose, service and get the most out of them.

What Are Conveyor Rollers?

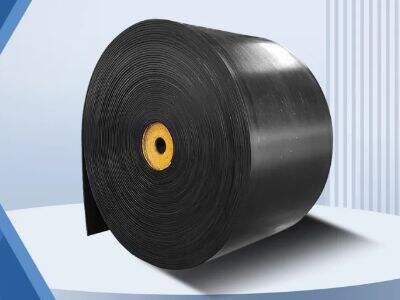

Conveyor rollers are round tubes and are typically made of cylindrical materials such as carbon steel or stainless steel. The rollers are available in various materials, such as plastic, metal or rubber, depending on their application. They are commonly used in manufacturing, logistics and distribution to move products quickly and safely. Working Of Conveyor Rollers Conveyor rollers spin along with the movement of the belt and the objects on top move at a quick speed too.

Understanding Different Types of Conveyor Rollers and Their Uses

Rubber conveyor rollers come in a variety of types that can be chosen depending on the type of operation. For one, gravity rollers help move items down or up an incline or decline without additional forklift power. These rollers use gravity to convey items. Another class of rollers is the power roller which is associated with a motor, or other driver device to drive articles along the conveyor belt. These rollers are frequently installed in large warehouses or distribution centers where goods need to be moved rapidly and cost-effectively.

Important Variables in Choosing Your Conveyor Idlers

Among the things to consider when selecting Belt conveyor roller for your application are:. The weight and size of the product being conveyed, as well as how fast the conveyor will be moving, and the environment in which the conveyor will be operating are also integral to proper roller selection. It is important to take all these factors into account for the purpose of smooth functioning and optimal performance of the conveyor system. Furthermore, opting for high-quality conveyor rollers from a reliable brand, such as Kilomega, can contribute to the longevity of the rollers, and cut down on maintenance expenses over time.

How to properly maintain and care for your conveyor rollers

Conveyor Roller Maintenance and Care Maintenance and care can be simple, here’s a few tips to keep your conveyor rollers performing properly. Regular inspections of the rollers for wear and tear, regular cleaning to rid them of dirt and debris, and regular lubrication to eliminate friction are all essential maintenance measures. It is also important to replace worn or worn-out rollers early on to prevent damage to the conveyor system. When you maintain your conveyor rollers properly, they will last longer and ensure that your conveyor system runs as it should.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

NL

NL

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TR

TR

AF

AF

GA

GA

BE

BE

MK

MK

MN

MN

NE

NE

KK

KK

UZ

UZ

KY

KY

XH

XH